Sustainability

Building a green future

With support from the Migros Pioneer Fund, two companies are showing that eco-friendly construction is feasible.

navigation

Sustainability

A new procedure enables a fearsome greenhouse gas to be used to make industrial alcohol. Migros Industrie is now turning this into cleaning agents. And these are now available for customers to buy.

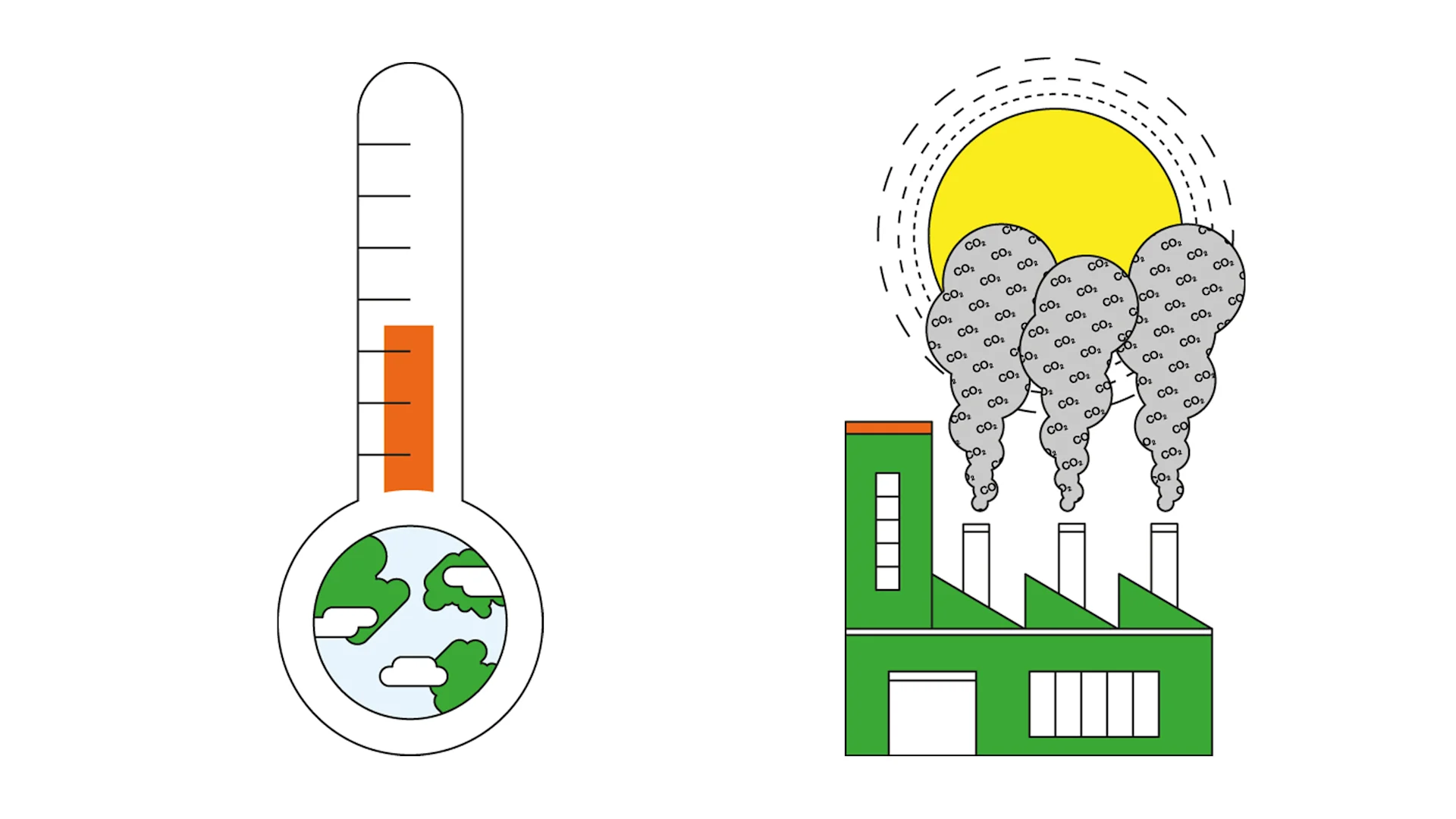

Our planet is constantly getting hotter. This is due to the greenhouse gas CO2, which is released into the atmosphere in large quantities by air travel and heavy industry, amongst others polluters. This causes a global greenhouse effect.

The most important remedy for climate change is to prevent CO2 from being created in the first place. Migros plays a part in this by transporting goods by rail whenever possible and operating solar arrays on the roofs of its buildings. Many other examples could also be listed.

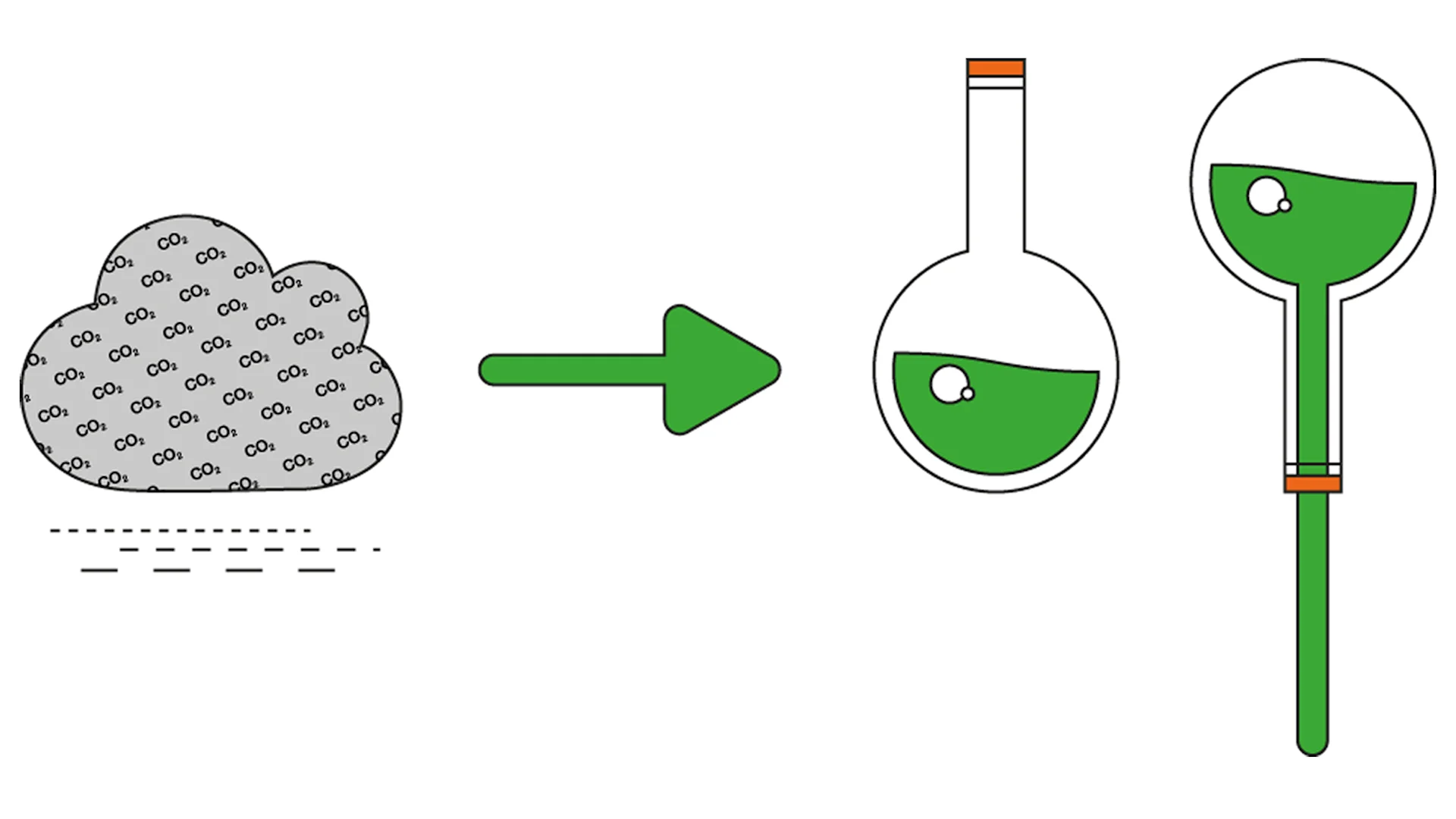

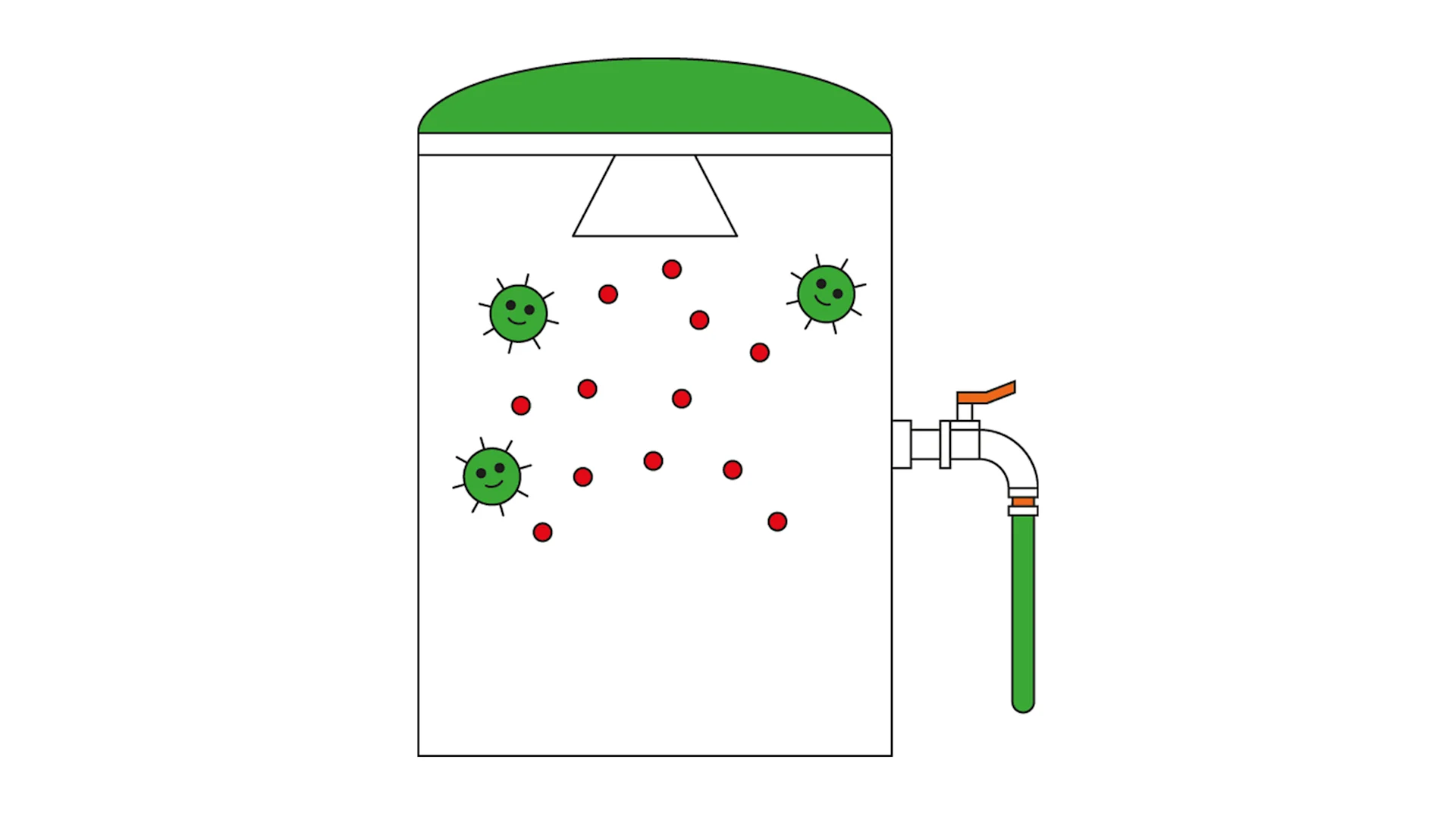

Unfortunately, CO2 emissions are unavoidable in major industrial sectors around the world, for instance in the production of steel. Here's where a new procedure developed by the American startup LanzaTech comes into play: this compresses CO2 and ferments in containers. The end product is liquid alcohol.

This transformation is made possible by special micro-organisms which feed on CO2 in the containers, thus causing fermentation. These tiny creatures are ancient life forms that already called our planet home when CO2 was still the predominant gas in the atmosphere.

The new procedure is initially being used at a steel plant in Hebei province in northern China. From the end of next year onwards, CO2 will also be captured and fermented at a modern steelworks in the Belgian city of Ghent. The Mibelle Group, a Migros subsidiary, is already using the alcohol produced in this environmentally friendly manner to make the cleaning agents sold under the Potz and Migros Plus brands. In 2020, about 80 tonnes of this ethanol were processed. That's 30% of the alcohol the company needs each year to manufacture cleaning agents. The aim is to increase this figure to 100% over the next two years.

Up to now, the alcohol used to make cleaning agents has often been obtained from sugar beet or sugar cane. The main problem here was the origin of the sugar cane: this often came from plantations in Brazil for which rainforest had previously been cleared. "The production of this new type of alcohol no longer requires any agricultural land," explains Susanna Heldmaier (53), the Strategic Lead of Basic Research & Technical Innovation at the Mibelle Group. "We can therefore preserve resources and contribute towards climate protection."

"The production of this new type of alcohol no longer requires any agricultural land"

Just how good is it for the climate to transport alcohol produced in China to Switzerland? "If you consider the entire life cycle of the alcohol, the delivery of the product hardly makes any difference in spite of the long distance," Heldmaier says. This life cycle assessment is checked within the framework of an independent study by the company Carbotech AG. The World Wide Fund for Nature (WWF) has also backed this new technology. Alcohol could one day partly also be made from CO2 in Switzerland – for example at waste incineration plants.

The Mibelle Group has ambitious plans: in the future, it wants to use this environmentally friendly alcohol to not only produce cleaning agents, but also for the packaging. The bottles for these cleaning agents are plastic (PET and PE). This plastic can be made from crude oil – or alcohol from recycled CO2.

Discover exciting stories about all aspects of Migros, our commitment and the people behind it. We also provide practical advice for everyday life.