Closing the loop

Reduce, reuse, recycle

We want to conserve resources and avoid waste in line with this concept.

navigation

Cycles in 2020-2025

As a retailer and producer, we have a major influence on waste quantities, recycling and circularity. Our strategy is therefore: reduce, reuse, recycle.

The population is growing, consumption is increasing and industrial production is reaching ever-higher peaks. As prosperity increases, so does the amount of waste.

If waste is not dealt with appropriately, this can have a significant negative impact on the environment and people’s health. These consequences often extend beyond the region in which the waste is produced or disposed of.

Contribution to climate change: incineration produces greenhouse gases such as CO2, and waste disposal and processing consume a lot of energy.

Lost materials: the finite resources and materials contained in waste that are sent to incineration or a landfill cannot be reused, thereby accelerating the depletion of these resources.

Pollution of the environment: the improper disposal of waste and littering lead to water, soil and air pollution.

Biodiversity: environmental pollution caused by inadequate waste disposal and the growing demand for new resources are increasing the pressure on ecosystems.

Health consequences: the emission of pollutants into the air or water can lead to illnesses, infections or other health problems.

Reduced quality of life: odours, vermin and visible litter disturb people who are looking to relax in nature.

Reusable waste is recycled and thus contributes to closing the material loop. The amount of municipal waste in Switzerland has increased by 50% since 1990. In the same period, the recycling rate in Switzerland has more than doubled.

We generate waste along the entire value chain: in production, operations, logistics, sales and at our customers’ homes. We must therefore manage waste prevention, separation and disposal responsibly along the entire value chain.

Waste, including food waste, occurs upstream of food production particularly during processing. Many of these types of waste can be avoided through in-house manufacturing. However, a large proportion is generated due to a lack of demand. These are known as preference losses, such as whey in cheese production or offal in meat processing. In the case of consumer goods, design and modular production have a major impact on the possibility of closing the loop. In these cases, we have no direct impact except through the selection of products for sale.

Various types of operational waste are generated in logistics and sales, including cardboard, refuse and unsaleable food.

In households, food waste is generated by the disposal of food. Consumer goods such as electrical appliances or furniture are also disposed of. In addition, packaging waste is generated by almost all products. Good packaging design (recyclability) and voluntary take-back of waste that is not required by law allow us to have a major influence on the amount of packaging material that can be returned to the cycle and used for new packaging. We thereby also make a positive contribution to the recycling infrastructure and the quality of recycling in Switzerland.

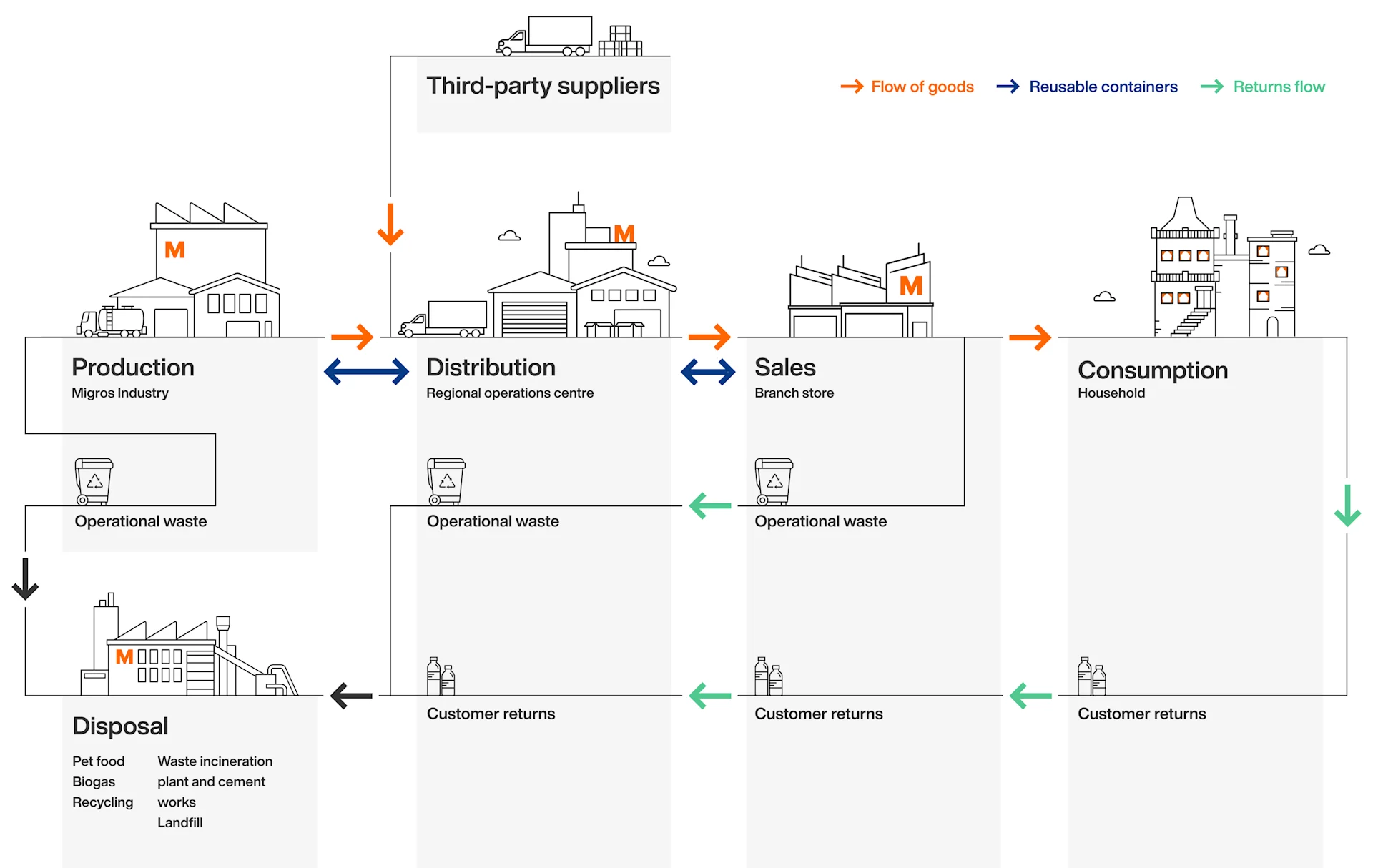

As a producer and distributor, our material flow ranges from production to the disposal of operational waste and customer returns. The products sold in the stores are delivered to the Cooperatives’ operations centres by Migros Industrie or third-party suppliers. Wherever possible, we use reusable containers in our logistics: products from Migros Industrie are transported to the operations centres in such reusable containers and further distribution to the stores also takes place in this way.

Packaging and products returned to the stores by customers flow back to the operations centres together with the stores’ operational waste and empty reusable containers. Whenever possible, existing empty space in Migros’ returns logistics is used for transportation. The waste is pressed into bales at the operations centres and transported by rail or truck to the relevant disposal companies.

Wherever possible, we apply the principles of closing the loop. This means using as few resources as necessary, reusing as much as possible, recycling waste to the greatest possible extent and returning it to the cycle.

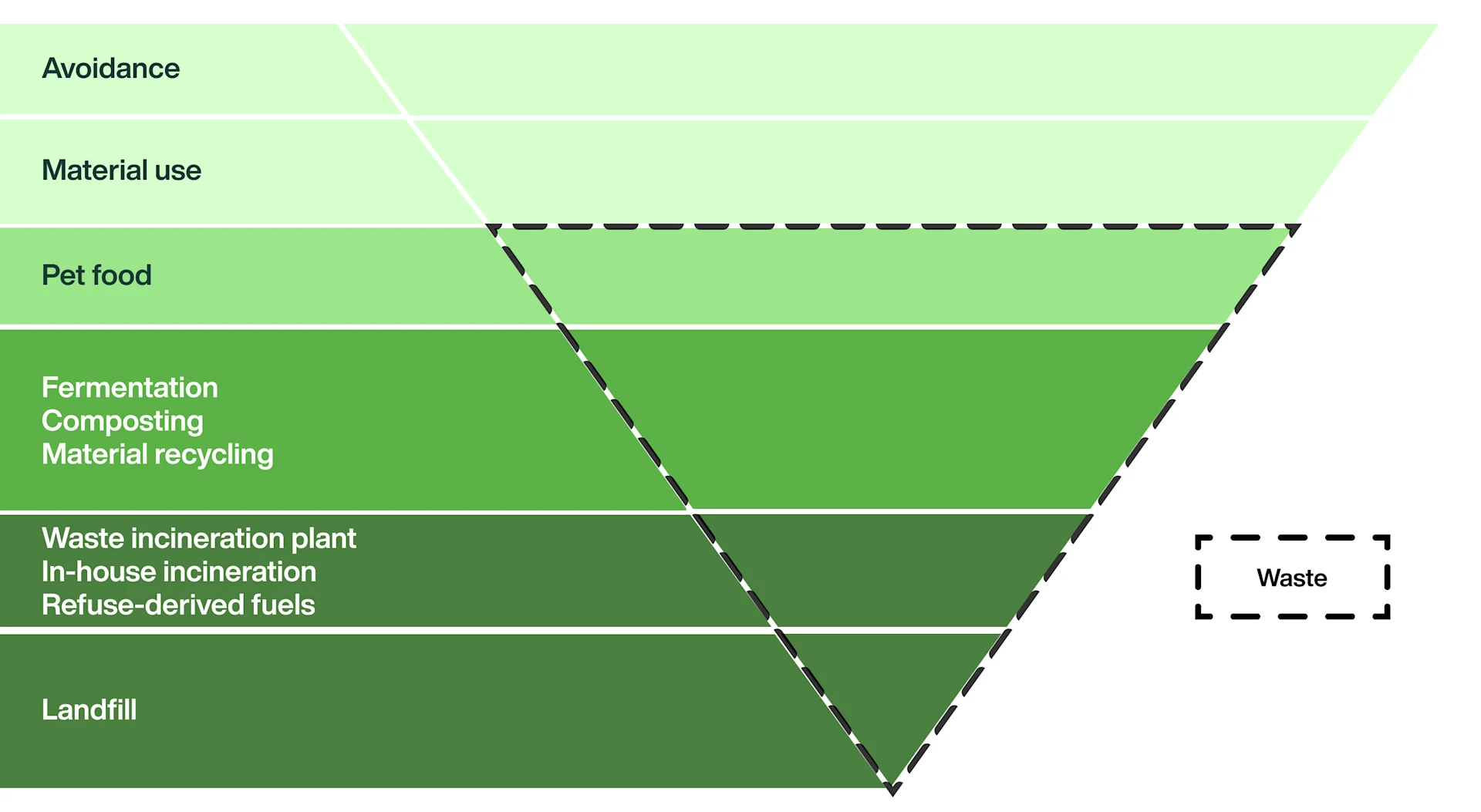

Our waste pyramid illustrates our overarching strategy for the most efficient waste management. The goal is simple: avoid waste as much as possible and recycle unavoidable waste to the highest achievable quality level.

Waste should be avoided wherever possible, and unavoidable waste should be recycled to a high standard and returned to the material cycle. We are constantly identifying further potential and developing new processes to reduce waste. We are also raising our employees’ awareness of how to separate waste correctly.

For example, we are investing in the Swiss recycling infrastructure and taking back more and more waste fractions than required by law in order to bring packaging materials back into the cycle. In 2012, we were pioneers in taking back CDs and DVDs. We have been taking back plastic bottles from the household sector since 2013 and aluminium coffee capsules since 2020.

In 2020, we went one step further: we now collect plastic packaging in selected regions using the Migros plastic collection bag. These are reused in the manufacture of new packaging in our own production facilities via Migros Industry.

We consistently apply ecodesign in the development of packaging and products.

We systematically avoid waste and repair products whenever possible.

We reduce our consumption of resources by consistently closing loops.

Our targets are based on scientific methods and are compatible with the Paris Climate Agreement. Thanks to clear annual reduction paths, we can transparently measure target achievement and – where necessary – make corrections to our approaches.

By the end of 2025, we will increase our recycling rate to at least 77.6% in our cooperatives.

By 2025, we will reduce the amount of unused waste in our cooperatives to a maximum of 26,286 tonnes.

By the end of 2025, employees from 1,190 stores will be trained in waste separation. This applies to supermarkets, hypermarkets and speciality markets as well as our restaurants.

By the end of 2025, we will test how we can benefit from circular-economy approaches in our speciality markets using three prototypes.

The strategic priorities and goals are reviewed and adjusted if necessary as part of business changes in the Migros Group and revision of the Sustainability Strategy.

Around 780,000 tonnes of plastic waste are produced in Switzerland every year. Most of this is disposed of properly. The majority is currently recycled thermally and energetically in waste incineration plants. Only around 10% is recycled and thus available for the manufacture of new products. This means that closing the loop still has great potential.

We are working at various points along the value chain to ensure that the loops can be closed further. For example, as a retailer, we offer a comprehensive take-back system for plastic packaging and are constantly expanding this in cooperation with our partners. As a producer, we reuse the recyclable materials we take back in the production of new packaging.

In Switzerland, less than 1% of plastic waste ends up in the environment. In order to keep this proportion as low as possible, we do not use plastic at all for products that are likely to become litter, such as disposable tableware and cutlery.

Microplastics are created by the degradation of larger plastic products or are used specifically in cosmetics, cleaning products and other consumer goods. Due to their size, microplastic particles can penetrate the ecosystem and have negative consequences for humans, animals and the environment. We are committed to reducing microplastics. For example, we do not use them at all in our cosmetic products.

Packaging is important for many products because it protects food from spoiling, thereby preventing food waste. Packaging a product is a science in and of itself. Each packaging unit must meet different requirements and is dependent on numerous factors.

An item of packaging should:

protect the product (shelf life and hygiene)

provide information (origin, ingredients, best before date, etc.)

present the product in an appealing way

be easy to transport in terms of logistics

be practical to use

be as environmentally friendly and recyclable as possible

cost very little

We are constantly optimising our product packaging and are only satisfied with a packaging unit if it has an optimum ratio of all the mentioned factors throughout its entire life cycle.

Closing the loop: we use recycled materials in the design of our environmentally friendly packaging and apply the principles of design for recycling.

Reusable instead of disposable: we use reusable packaging wherever feasible and are expanding our range of unpackaged products.

Material reduction: as a rule of thumb, the lighter the packaging, the more environmentally friendly it is.

Innovative packaging solutions: new materials and packaging solutions are constantly being tested.

The M-Check rating system for environmentally friendly packaging is a simplified life cycle assessment that shows our customers at a glance how environmentally friendly an item of packaging is.

Our targets are based on scientific methods and are compatible with the Paris Climate Agreement. Thanks to clear annual reduction paths, we can transparently measure target achievement and – where necessary – make corrections to our approaches.

By the end of 2025, 55 stores in 10 cooperatives will offer zero-waste filling stations for food.

By the end of 2025, our products in supermarkets and hypermarkets will be 100% microplastic-free.

By the end of 2025, at least one product in each product group (e.g. potatoes or tomatoes) in our supermarkets and hypermarkets will be offered unpackaged and at least one product in plastic-free packaging.

By the end of 2025, we will reduce the packaging material used for all Migros Industry products, including exports, by 5% compared to 2020.

By the end of 2025, all Migros Industry packaging, including for exports, will be recyclable.

By the end of 2025, all Migros Industry packaging, including for exports, will consist of 50% recycled materials.

By the end of 2025, 60% of all Migros Industry packaging, including for exports, will be made from renewable raw materials.

The strategic priorities and goals are reviewed and adjusted if necessary as part of business changes in the Migros Group and revision of the Sustainability Strategy.

The global production of food is very resource-intensive and consumes a lot of land, water and nutrients. According to the UN, the production, transport and waste of food is responsible for 8% of global greenhouse gas emissions. It is estimated that in Switzerland around a third of all edible food is lost or wasted between field and plate (source: Federal Office for the Environment FOEN). We are therefore working to keep food waste to a minimum.

We are reducing food waste along the value-added chain.

The key measure for keeping food waste to a minimum is optimal planning when procuring food. This includes the most precise possible quantity planning in stores as well as tailored transport routes and delivery times. These actions are having an effect: we sell almost 99% of all food or donate it to charitable organisations. The rest is mostly recycled to a high-quality level – as biogas, animal feed or compost.

The Migros Group has signed the FOEN’s cross-industry agreement and is a member of “United Against Waste”. Our aim is to implement the Federal Government’s Food Waste Action Plan to halve food waste along the entire value chain.

Our targets are based on scientific methods and are compatible with the Paris Climate Agreement. Thanks to clear annual reduction paths, we can transparently measure target achievement and – where necessary – make corrections to our approaches.

By the end of 2025, we will reduce food waste in our supermarkets and hypermarkets by 20% to a total of 1.07%..

We support the upstream and downstream value chains in measurably reducing their food waste. By 2025, at least one measure must be implemented in our supermarkets and hypermarkets every year.

The strategic priorities and goals are reviewed and adjusted if necessary as part of business changes in the Migros Group and revision of the Sustainability Strategy.

The circular economy offers an answer to the climate and biodiversity crises and enables greater independence from imports. A transformation to a circular economy eliminates waste and thus also pollution. It also reduces the need for new raw materials, which can reduce the pressure on ecosystems and their diversity.

Many everyday items can be reused or shared in order to extend the product life cycle and save resources. Renting instead of owning, sharing, second-hand instead of buying new, or reprocessing: these business models improve the useful life and usage intensity of high-quality products. This is why we are increasingly offering used products or products for rent and focusing on new business models in this area.

We consistently apply ecodesign in the development of packaging and products.

We systematically avoid waste and repair products whenever possible.

We reduce our consumption of resources by consistently closing loops.

The strategic priorities and goals are reviewed and adjusted if necessary as part of business changes in the Migros Group and revision of the Sustainability Strategy.

We continue researching so that no plastic goes unused and we find solutions to avoid waste. Find out exactly how we do this in our Stories.